What is Exagan's technological breakthrough?

Fabrice Letertre: We are using a revolutionary material - gallium nitride (GaN) - to make a new generation of power transistors that offer ten times the performance of the silicon-based transistors currently used around the world in power electronics. This innovation will allow us to make smaller electric power converters that are more efficient and consume less energy. Some of the main uses for power converters are in telephone chargers, computers, televisions and electric car chargers. The technology will also be useful in datacenters, which are currently facing major challenges in terms of energy consumption. Our aim is to achieve 99% efficiency for all electric power converters.

Where did this innovation originate?

F.L.: Gallium nitride's properties have been known for a long time, because it is used to make LED lightbulbs. In the early 2000s, teams at CNRS in France discovered how to deposit gallium nitride onto silicon wafers in order to produce transistors. The technology was then developed jointly by LETI (the electronics lab of the CEA, the French Alternative Energies and Atomic Energy Commission) and Soitec, a global leader in the production of innovative semiconductor materials.

What is the current stage of development?

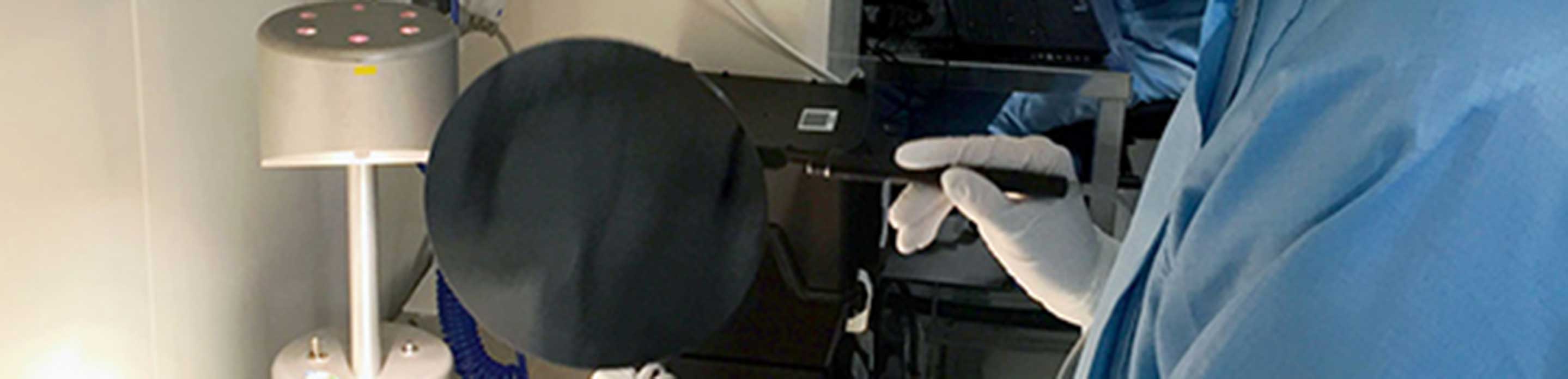

Frédéric Dupont: In 2014, Exagan, a spin-off from Soitec and the CEA, was set up to manufacture and market GaN-on-silicon technology. After an initial phase in which we demonstrated the feasibility of these transistors, we formed various industrial partnerships. In Grenoble, we produce GaN wafers in our clean room, using proprietary expertise. The wafers are then etched in Germany at X-Fab a semiconductor producer. After the chips have been cut and packaged , they are sent back to Toulouse for final testing by Tüv Nord, a leading certification company for the auto and aerospace sectors. We are now working to set up a commercial structure that will provide both sales and technical customer support on an international scale. We are currently in advanced negotiations with several leading OEMs in the consumer electronics, automotive and industrial controls fields.

Who is financing this build-up process?

F.D.: As well as the innovation grants we have received, we closed our first round of funding in 2015, raising money from both long-standing shareholders and experienced high-tech industry VC investors . The latter included Crédit Mutuel Innovation (formerly CM-CIC Innovation) which, as well as specialising in this field, shares our entrepreneurial values and supports our ambitions and development. We are planning a second round of fundraising this year in order to bring our products to market.

What the partner says

Frédéric Dupont and Fabrice Letertre, Exagan's two co-founders, are experts in the semiconductor field. They guide the company's strategy with their shared vision of how the power electronics market is developing. Their experience at Soitec, in conjunction with the CEA, was an excellent basis for Exagan's creation as part of a supportive ecosystem. In 2015, they convinced us to work with them, at a time when the company was barely a year old.

To bring to market a new generation of electronic components that represent a complete break with existing products, Exagan needs to convince market-leading customers to adopt its first generation of chips and integrate them into their own products.

Today, as the chips are entering production on an industrial scale, marketing is about to become Exagan's key challenge. As a result, Crédit Mutuel Innovation is guiding the company's management team in the fundraising round that will provide Exagan the financial resources to market its products. These products will become ubiquitous in our daily lives over the next few years: for example, we should see Exagan chips widely used in PC chargers and electric vehicles.

€5,0 m raised in the Series A fundraising in 2015

30 employees across three sites in France

3

strategic partnerships

(production-certification-sales)